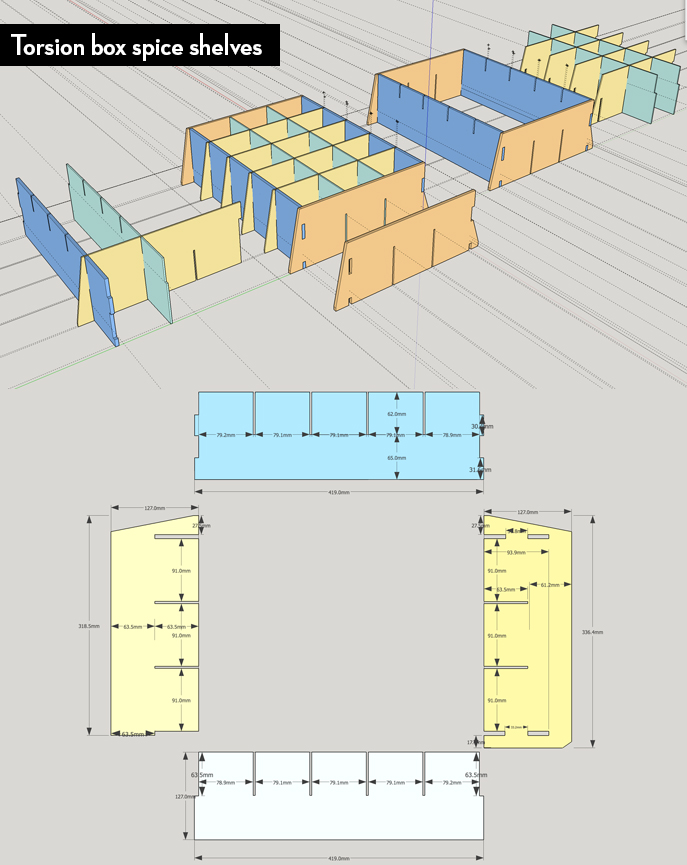

Projects run on the Epilog Laser cutters at E&M Labs: After hours, I got to design and cut my own projects! Once we hit our holiday shipping deadline, I got to really run the laser cutters through their paces, trying out personal projects and testing ideas. Here’s some screenshots from the torsion box shelves I designed to use up the piles of scrap wood we had from all the laser-cut siege engines. We had a lot of scrap wood of a certain size, and I have a lot of spices. I also wanted to build in an interchangeable label system, so the labels pop in and out based on some mild friction on the side, and they also help keep the spices secure. Bonus: lasers have better handwriting than I do. (It was also an excuse to learn Sketchup, which I had been meaning to do for some time.)

After hours, I got to design and cut my own projects! Once we hit our holiday shipping deadline, I got to really run the laser cutters through their paces, trying out personal projects and testing ideas. Here’s some screenshots from the torsion box shelves I designed to use up the piles of scrap wood we had from all the laser-cut siege engines. We had a lot of scrap wood of a certain size, and I have a lot of spices. I also wanted to build in an interchangeable label system, so the labels pop in and out based on some mild friction on the side, and they also help keep the spices secure. Bonus: lasers have better handwriting than I do. (It was also an excuse to learn Sketchup, which I had been meaning to do for some time.)

I also started prototyping my idea of 3d topographic-map puzzles: the pieces snap into place in the 1mm-deep carved out darker areas, one topographic slice at a time. This demo prototype is a super-simplified terrain: in the final version I want to take accurate USGS data, simplify and vertically scale it, and create vector files that one could laser-cut. That way you could actually show a child (or an adult) things like how steep their neighborhood is, or what the mountain ranges (simplified) of California really look like. I was thinking having a thin decorative pattern layer of road lines or terrain types to help ground the pieces. Obviously a CNC router would probably do a better job…but when you have two laser cutters, you end up thinking in stacked 2d all the time.

More laser tinkering: I wasn’t very happy with the way Epilog lasers did “raster” settings, so I was experimenting a lot with 19th century wood-cutting techniques to get areas of darkness– which is how I got silly stuff like this iPad fireplace frame I designed to have two different levels of darkness, beyond what the Epilog printer drivers could create. (The darker tone is a mass of deeper cuts to use shadow, not just laser kerf.)

Some of my posable creature sculpts, from 2009-2010:

And some promotional photography stunts done to show off the Desktop Siege Engines:

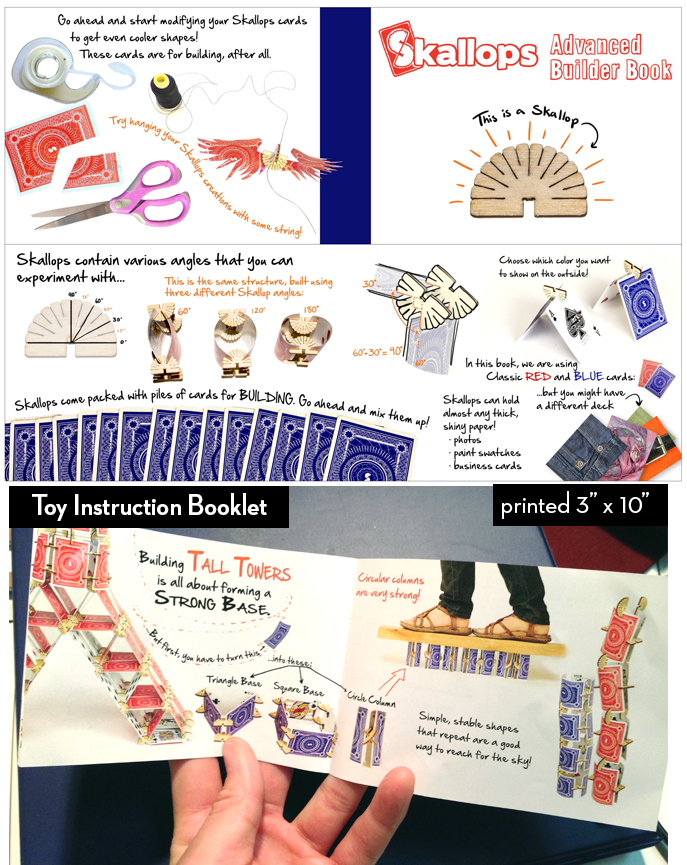

Skallops Advanced Builder Book: (Full instruction manual here.)